6-20 个字符(仅限字母加数字)

密码不一致

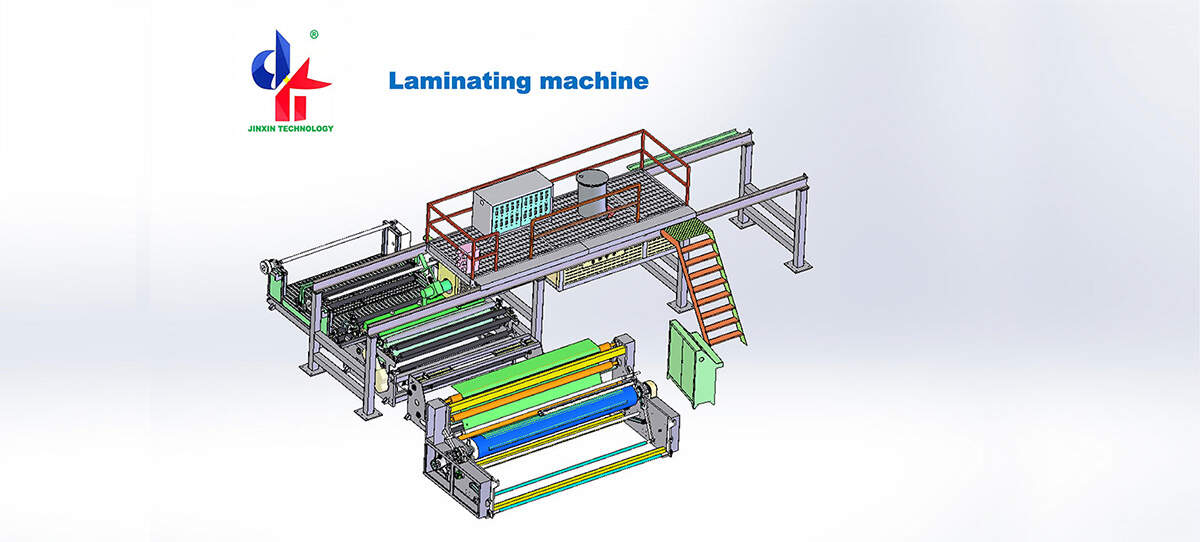

Good Price Ultrasonic Laminating and Coating Machine for Non-Woven Filter Material

The high-frequency ultrasonic vibrations used by the ultrasonic non-woven laminating machine are forced into the nonwoven materials. The contact points between the two pieces, which are commonly made of cloth, cloth and chemical fiber, plastic film, and plastic film, as well as other materials like cotton, nonwoven fabric, sponge, etc., melt and bind as a result of these vibrations, forming a solid junction.

This ultrasonic lamination machine may be made to order with a variety of designs that are adapted to the desires of the customer, and the laminating size can be altered in accordance with the size of the material roll.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Product Description

The ultrasonic non-woven laminating machine adopts high-frequency ultrasonic vibrations that are transmitted into the nonwoven materials under pressure. These vibrations cause the contact points to melt and bond, creating a solid joint between the two parts, typically cloth and cloth, cloth and chemical fiber, plastic film, and plastic film, and other materials such as cotton, nonwoven fabric, sponge, etc.

This ultrasonic lamination machine can be custom manufactured with various patterns tailored to customer preferences, and laminating size is customizable according to the material roll size.

The machine is offered in various configurations tailored to the customer’s specific needs, available in single roller, dual rollers, three rollers, and four rollers. And the vibrator can be driven by a mechanical system, pneumatic cylinder, or hydraulic system.)

Product Applications

Materials: PVC tape, PE tape, EVA tape, PU latex leather, PP non-woven fabric, filter paper, nylon fabric, polyester fabric, pongee, Oxford cloth, polyester taffeta, TC fabric, and other materials containing chemical fiber;

Industries: artificial leather, non-woven fabric, thermoplastic film, chemical plastic sheet, knitting, printing, clothing lining, shoe making, baby and adult diaper, changing mat, sanitary pad, seat cushion, non-slip mat, bulletproof vest, bedding, and automotive filter material.

Product Features

Utilizing ultrasonic welding technology to replace conventional sewing method, eliminating the need for needles, thread, or other consumables, providing strong bonding and superior embossing effect;

An ultrasonic system with a specially manufactured steel roller enables the edge to be sealed perfectly without fraying or unraveling;

The anvil roller is equipped with an adjusting unit that can quickly adjust the anvil roller level (anvil roller can be custom manufactured according to customer required patterns);

It can be designed with functions of finished product slitting and crosscutting, and double-station rotation winding according to the customer’s requirements;

Tension control guarantees smooth rewinding, and the ultrasonic sonotrode is adjustable in horizontal motion;

The ultrasonic system features stable power output, providing uniform welding while improving work efficiency. Automated running is carried out by a microcomputer, easy to operate.