6-20 个字符(仅限字母加数字)

密码不一致

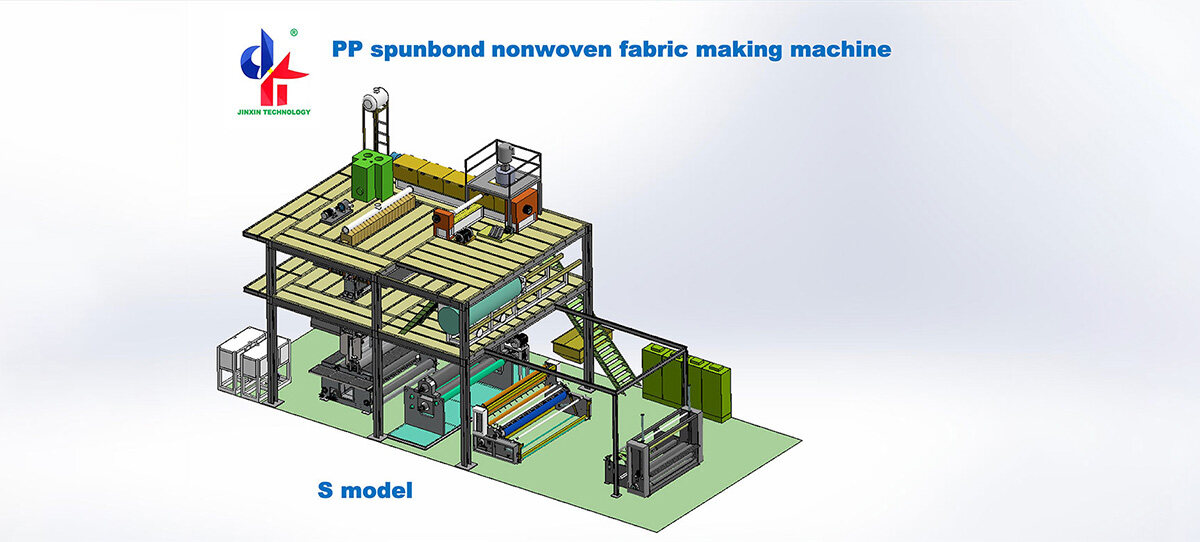

2400mm S type nonwoven equipment

It is forbidden for the spunbond nonwoven fabric machine to let too much water or oil into the pressure system. If it is possible to check that the oil volume of each inner cup of the converter is sufficient, this will help prevent issues, shorten the life of the cylinder barrel, and ensure that the air is dried and cleaned. If not, the pressure relief valve should be pushed forwards and should not be used for an extended period of time at the back.

| Model | JX-S |

|---|---|

| Product Width | 2400mm |

| Equipment Size | 20*10*12m |

| Mechanical Speed | 150m/min |

| Gram Weight | 10-200g/m2 |

| Daily Output | 7-8T/Day |

| Transformer Capacity | ≈250KVA |

| Power Consumption | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Technological process of S spunbond nonwoven fabric machine

Feeding (non-woven fabric coil), folding, acoustic bonding, cutting, bag making (punching), waste recycling, counting, and stacking. To further realize the role of energy conservation and environmental protection, it has the function of recycling surplus materials in the production process. It actively collects the waste materials left in the production process, which is helpful for secondary use, reduces labor intensity, increases work efficiency, and conforms to the concept of environmental protection. It can also save corresponding costs. The spun-bond nonwoven fabric machinery will continue to develop towards increasing the machine width, improving the speed and capacity of a single machine, paying attention to the processing accuracy of the equipment and selecting new materials, improving the level of electromechanical integration, and further using the computer online detection and control and network system to ensure high-yield and high-quality production.

Daily maintenance of S spunbond nonwoven fabric machine

The spunbond nonwoven fabric machine shall not allow too much water and oil to enter the pressure system. To prevent problems, shorten the service life of the cylinder barrel, and ensure the drying and cleaning of the air, if it is possible to check that the oil volume of each inner cup of the converter is sufficient, the pressure relief valve shall not be used for a long time at the rear end and shall be pushed forward. When the operation is stopped, the power switch shall be closed, and the compressed air control valve, the shaft barrel, and all parts shall be prevented from magnetic loss. The side sliding seat parts and precision and highly complex parts of the installation platform are often wiped clean and oiled for maintenance to prevent the influence of rust on accuracy.

Pay attention to the protection of the environment and machinery. The workshop environment should be clean. Before the operation, it is necessary to clean up. Voltage and power detection should ensure that the voltage is applied to prevent the voltage from being too high or too low. Do not use it to be polluted or touched by hands.