6-20 个字符(仅限字母加数字)

密码不一致

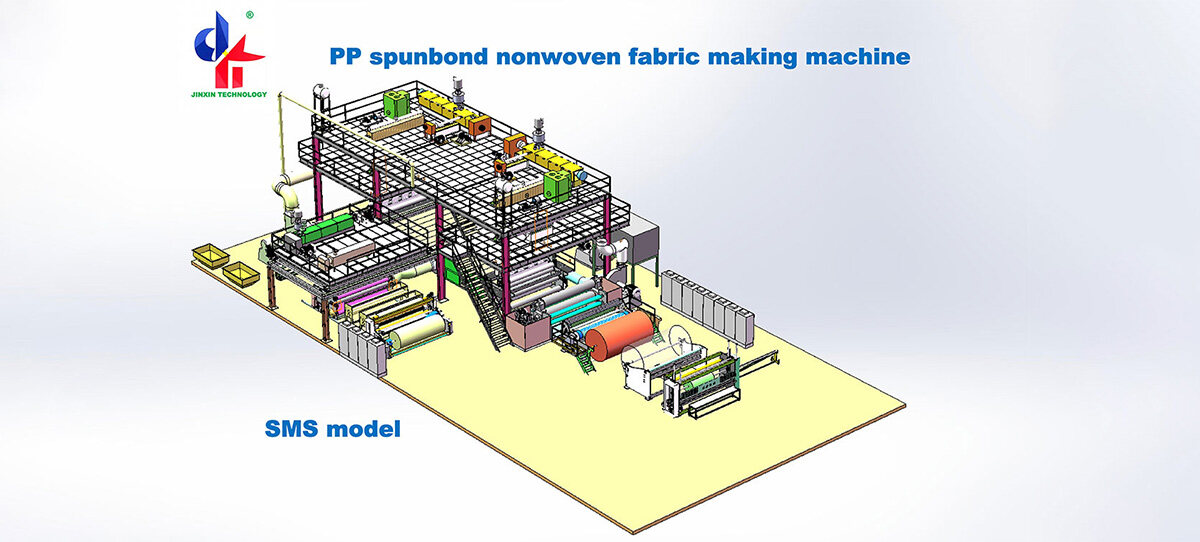

SMS nonwoven machine production line

The SMS Nonwoven Production Line, which combines spunbond and meltblown manufacturing processes, is a composite line for the production of nonwoven materials. The web is made up of three layers: the first layer is created by the first spunbond spinning system, the second layer is created by the second spunbond spinning system, and the third layer is created by the melt-blown spinning system. To create an SMS composite Non-woven Fabric, the three-layer web is first hot-rolled together, then cut and wound by a rolling machine.

| Model | JX-SMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 40*16*12m | 40*18*12m | 40*22*12m |

| Mechanical Speed | 400m/min | 400m/min | 400m/min |

| Gram Weight | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Daily Output | 8-12T/Day | 12-16T/Days | 16-22T/ Day |

| Transformer Capacity | ≈800KVA | ≈1250KVA | ≈1600KVA |

| Power Consumption | 1200°-1650°Ton | 1200°-1650°Ton | 1200°-1650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

The SMS Nonwoven Production Line is well designed as three beams while combining spunbond and meltblown manufacturing techniques, they are composite lines for nonwoven production.

The first spunbond spinning system forms the first layer of the web, and then the melt-blown spinning system makes the second layer of the web, and then the second spunbond spinning system forms the third layer of the web. The three-layer web is bonded by the hot-rolling machine, and finally, slit and wound by a rolling machine to form an SMS composite Non-woven Fabric.

Technical Advantages

1) The whole line is well-structured and easy to operate.

2) The whole line is highly automated.

3) Control elements are of well-known make, high performance, and reliable technologies.

4) The whole line is controlled by PLC and operated with a touch-screen.

5) The allocation of the main frame and auxiliary equipment can be specially designed and adjusted according to customers' requirements.

Application

Nonwoven Packaging Product

Shopping bags, rice packaging, tea bags, clothes packaging, etc.

Nonwoven Hygiene Product

Baby and adult diapers: Top sheets, back sheets, ears, tapes, landing zone;

Female hygiene: Top sheets, wings;

Cleaning wipes: Baby care, cosmetics, etc.

Nonwoven Medical Product

Surgeon's Cap, surgeon's mask, disposable garments, surgical drapes, surgical sheet, shoe covers, etc.

Nonwoven Technical Product

Geotextiles: Erosion protection, filtration, reinforcement, drainage, separation layers, embankment fortification, etc. for streets, dikes, and farms.

Structural engineering: Bitumen supports, roof insulation sheeting, diaphragms.

Agriculture: Crop forcing nonwovens, insect protection, etc.

Automotive: Inner paneling, sound insulation, insulation, etc.

Nonwoven Furniture Product

Beds: Pocket springs, mattresses, cushions, bed covers, disposal bedding.

Seating: Upholstered backs, sub-paneling, intermediate layers, etc.

Production Application

This polypropylene (PP) SMS nonwoven fabric production line has the advantages of superior performance, beautiful color, and good quality. It can form a fiber web symmetrically and is complete in types. It can also add recycled material and stuffing to reduce the cost of products.