6-20 个字符(仅限字母加数字)

密码不一致

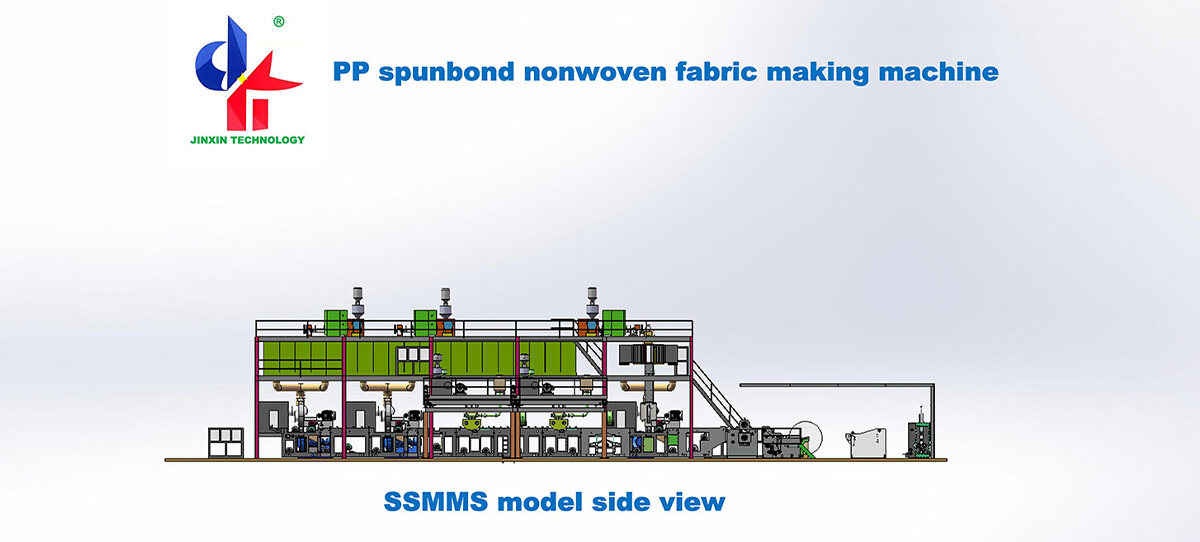

SSMMS spunbond nonwoven fabric making machine

The major purposes of a nonwoven fabric manufacturing machine are its small structure and overall modular design. It is a common method for creating goods made of non-woven fabric. The machine's shield configuration for manufacturing nonwoven fabrics ensures worker safety during operation and gives workers access to improved and safer production tools.

| Model | JX-SSMMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 60*18*12m | 60*20*12m | 60*25*12m |

| Mechanical Speed | 600m/min | 600m/min | 600m/min |

| Gram Weight | 8-120g/m2 | 8-120g/m2 | 8-120g/m2 |

| Daily Output | 10-16T/Day | 16-25T/Day | 22-35T/ Day |

| Transformer Capacity | ≈1350KVA | ≈1600KVA | ≈2300KVA |

| Power Consumption | 1200°-1850°Ton | 1200°-1850°Ton | 1200°-1850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Nonwoven fabric making machine is mainly used for overall modular design and compact structure. It is a general mechanism for producing non-woven fabric products. The nonwoven fabric making machine shield configured by the machine ensures the safety of workers' effective operation and provides workers with safer and better production equipment.

What should be paid attention to in the weaving of nonwoven fabric making machines?

The nonwoven fabric making machine needs to be cleaned frequently and oiled for maintenance to prevent the influence of rusting on the precision of the sliding seat parts on the device workbench and the precise and highly complex environment. Attention shall be paid to environmental and mechanical protection. The workshop environment shall be clean and clean before work. Voltage and power inspection shall keep the voltage within its application range to avoid high or low voltage. Do not touch with hands.

The nonwoven fabric making machine shall not allow excess water and oil to enter the pressure system. To avoid failure, shorten the service life of the cylinder barrel, and keep the air dry and clean. If possible, check each inner cup of the converter. When the oil quantity is sufficient, the pressure relief valve should not be used at the rear end for a long time and should be pushed. When the work is stopped, the power switch should be turned off. The compressed air control valve, the shaft barrel, and each side should avoid magnetic consumption.

To maintain the normal and stable operation of the flame-retardant nonwoven fabric making machine in the rugged speed section during the working process, when the capacity of the frequency converter is selected, the power of the exchange frequency converter shall be increased.

In a unit machine, static performance and dynamic and static performance are equally important. By optimizing the adjustment of the response parameters in the frequency converter, a more enjoyable static performance can be achieved. At the same time, after the on-site measurement is compared with the surface, the parameters can be adjusted in the PLC program for calibration, to eliminate the static error caused by the objective conditions in the surface calculation. Dynamic and static synchronization is also very important. Its function mainly refers to whether the change of the line speed of the unit machine is consistent in the process of raising and lowering speed.

The manufacturing speed of the manufacturing line is very fast, and the requirements for synchronous realization are also very high. This feature should be fully considered in the design. Therefore, the method of synchronous control is accepted. The transmission frequency converters of the wire laying machine and winding machine exchange data mainly through the data interface of PLC. If you want to achieve the dynamic and static results of freehand writing, you must realize that digital communication and the rise and fall rate of the manufacturing line are good dynamic and static results. To ensure the synchronous effect between the wire laying machine and the winder, the winder is also equipped with a tension control system.