6-20 个字符(仅限字母加数字)

密码不一致

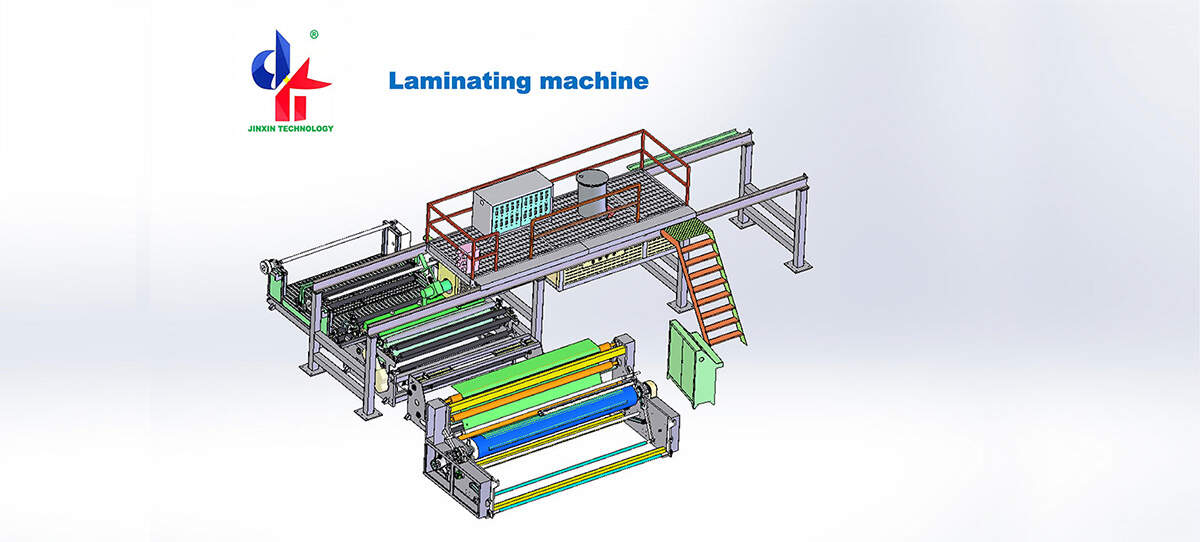

Automatic Shopping Bag Medical Non-Woven Gown Fabric Coating Making Machine

This machine is a high-quality supply in the same industry and has the features of a fully automatic weight control system, a fully automatic material receipt and refilling PLC control system, and a man-machine operation interface. The double-die can apply edge cutting, edge-blowing, cutting-off, and winding devices automatically. It can also do single or double-face coating and regulate the coating and laminating width.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Product Description

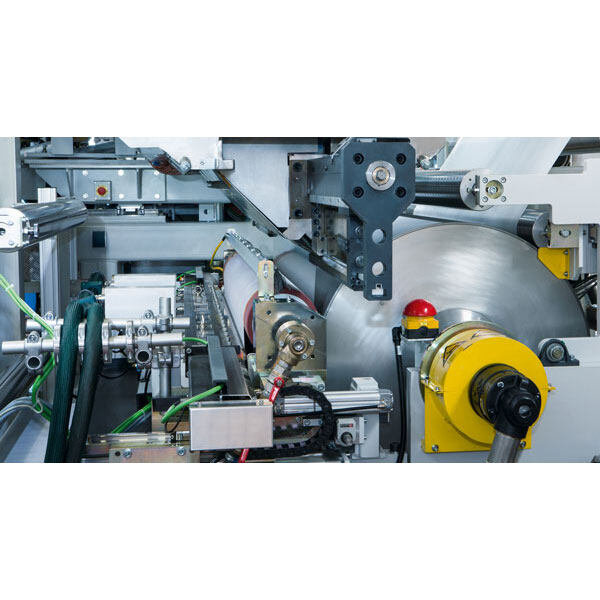

Aesthetically and ergonomically build a machine for best performance;

Produced in an advanced state-of-the-art manufacturing facility;

World-class bought out items for optimum operations;

Efficient control panel to set important operative parameters easily;

Designed to work 24 hours, round the clock;

Operator-friendly machine, hence easy to operate and maintain;

Low maintenance and operating cost;

Sturdy design to ensure long life and trouble-free operation.

Performance and Characteristics for Gown Fabric Making Machine

(1)The double-die can do single or double-face coating, the width of coating&laminating can be regulated, and automatically automatic edge cutting, edge-blowing, cutting-off, and winding devices are applied.

(2)This machine has the functions of a fully automatic material receiving and refueling PLC control system, a fully automatic weight control system, and a man-machine operation interface, and it is a high-quality supply in the same industry.

FAQ

What is the classification of surgical gowns?

1.Cotton surgical gown. Surgical gowns, which are the most widely used and most dependent in medical institutions, have good air permeability but poor barrier protection. The cotton material is prone to flocculation, which makes the maintenance cost of the hospital's ventilation equipment a lot of burdens.

2.High-density polyester fabric. This type of fabric is mainly made of polyester fiber, and conductive substances are embedded on the surface of the fabric so that the fabric has a certain antistatic effect, which improves the comfort of the wearer. This kind of fabric has a certain degree of hydrophobicity, is not easy to produce cotton bleaching, and has the advantages of a high repeated use rate. This kind of fabric has a good antibacterial effect.

3.PE (polyethylene), TPU (thermoplastic polyurethane elastic rubber), PTFE (Teflon) multilayer laminated film composite surgical gown. The surgical gown has excellent protective performance and comfortable breathability, which can effectively block the penetration of blood, bacteria, and even viruses. But the domestic popularity is not very wide.

4.(PP) Polypropylene spun-bond fabric. Compared with traditional cotton surgical gowns, this material can be used as a disposable surgical gown because of its low price and certain advantages such as antibacterial and antistatic. However, this material has a comparatively high resistance to hydrostatic pressure. Low and the barrier effect to the virus is relatively poor, so it can only be used as a sterile surgical gown.

5.Polyester fiber and wood pulp composite spun cloth. Generally only used as a material for disposable surgical gowns.

6.Polypropylene spunbond-meltblown-spun. Adhesive composite non-fabric (ie SMS or SMMS): This material is a high-quality product of a new type of composite material. The material has high resistance after being treated with three antibodies (anti-alcohol, anti-blood, and anti-oil), antistatic and antibacterial Hydrostatic pressure capacity. SMS nonwoven fabrics are widely used at home and abroad, often used to make high-end surgical gowns.