6-20 个字符(仅限字母加数字)

密码不一致

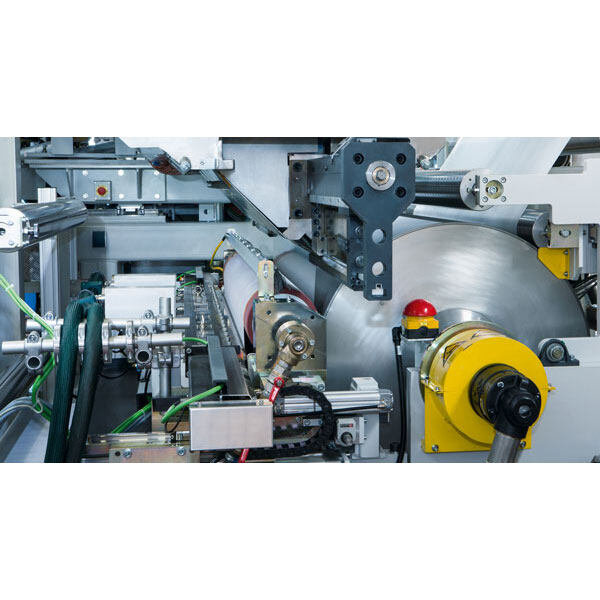

Laminating Machine

Laminating Machine

(17)best nonwoven lamination machine for sale.

Welcome to our online store, We are a professional china non woven fabric making machine and automatic laminating machine manufacturer that has a wide variety of automatic laminating machines for sale, such as the 2022 Latest Digital Manual Dry Wet Textile Extrusion Coating Non-Woven Fabric Laminating Machine, Nonwoven Materials Hotmelt Coating and Laminating Machine for Disposable Medical Surgical Gown Bags, High-Speed Multifunction Fully Automatic Nonwoven Fabric Laminating Production Line, Hot Selling Non-Woven Fabric Coating Lamination Plant Machine From China, and so on.

Our laminating machines use moisture-reactive hot melt adhesives to laminate fabrics with thin films for a variety of functional fabric products. Fabric materials that can be laminated are woven fabrics, knitted fabrics, non-woven fabrics, and many polymers/elastomers. These laminating machines are also used for the production of self-adhesive products, such as self-adhesive, double-sided adhesive, foam tape, aluminum foil tape, cleaning tape, paper tape, etc. It is also suitable for the composite of different materials, such as non-woven fabrics, filter materials, shoe materials, medical materials, labels, films, etc.

If you are interested in our products, please feel free to contact us.

Good Price Ultrasonic Laminating and Coating Machine for Non-Woven Filter Material

The high-frequency ultrasonic vibrations used by the ultrasonic non-woven laminating machine are forced into the nonwoven materials. The contact points between the two pieces, which are commonly made of cloth, cloth and chemical fiber, plastic film, and plastic film, as well as other materials like cotton, nonwoven fabric, sponge, etc., melt and bind as a result of these vibrations, forming a solid junction. This ultrasonic lamination machine may be made to order with a variety of designs that are adapted to the desires of the customer, and the laminating size can be altered in accordance with the size of the material roll.

Automatic Coated Production Line Laminating Machine Jumbo Roll Slitter Rewinder Lamination Machine

This slitter machine uses surface contacting and winding in addition to center winding. It has an invariable tension magnetic powder brake and clutch as well as a photoelectric automated deviation rectification device. The main engine uses frequency control, and the air cylinder manages the cot's movement. Additionally, it contains an automated stopping device and a meter that calculates measurements automatically.

2022 Latest Digital Manual Dry Wet Textile Extrusion Coating Non-Woven Fabric Laminating Machine

This highly automated device has sophisticated construction, intuitive operation, little power consumption, and great productivity. To achieve consistent compounding, it uses twin extrusion-dies with compounded double-rollers. All of its completed products are high intensity and perform well in terms of look and application. This machine has an auto-correcting mechanism for automatically transmitting and guiding produced material. It is simple to use and has adjustable speed.

New High Efficient Automatic PP Nonwoven Bag Fabric Machine/Extrusion Lamination Coating Machine

The non-woven fabric bag-making machine can process a variety of non-woven fabric bags with diverse specifications and shapes, including vest bags, purses, leather bags, and so on. Non-woven fabric fruit bags, plastic turnover basket bags, apple bags, and grape bags are just a few of the industrial bags that have recently been added to the market. The machine combines mechanical and electronic components and uses a touch screen for operation.

Best Price Nonwoven Roll Lamination Coating Machine Manufacturer

This extrusion laminating machine processes by melting the plastic to extrude from the T-die mould and then laminating with the base material. This type of machine has been widely utilised for the lamination of substrates such as paper, non-woven fabric, woven fabric, aluminium foil, BOPP film, etc. The final product is renowned for its excellent fastness, thickness homogeneity, and strong sealing ability.

High Speed Protective Garments Fabric Non Woven Paper/PE/BOPP Breathable Film Compound Laminating and Coating Machine

Our advancement is reliant on the best machinery, top-notch personnel, and consistently developed technological forces for nonwoven fabric manufacturing. Under the condition of efficiency and efficiency improvement, we want to foster harmony among our employees and business growth. We should operate ethically and contribute to the creation of a civil society and the raising of people's standards of living.

China Factory Manufacture High Speed Multifunction Fully Automatic Nonwoven Fabric Laminating Production Line

There are several designs, hues, and patterns of laminated nonwoven fabric to choose from. It features a high level of fluid protection and is waterproof. Designing isolation gowns, surgical gowns, drapes & covers, scrub suits, food grain packaging, shopping bags, etc. uses laminated fabrics. creating the best result by combining non-woven with various types of specialty film & other additives.

Full Automatic Best Price and Hot Selling Non Woven Fabric Coating Lamination Plant Machine From China

The main objective of businesses that produce nonwoven laminates is to increase production speed while maintaining the caliber of the finished product and the reels that hold it. This calls for a machine that will let you manage the web tension and speed during the entire operation.

High Speed Fabric Laminating Press Production Line, Extrusion Film Non Woven Laminating Machine with Cheap Price

to reduce film threading time and reduce web path waste. To achieve consistent high-quality coating gauge and reliable performance, the machine uses top brands. To obtain well-mixed resin, the screw and barrel have undergone stringent design and treatment. All un/rewinders have continuous turret auto splicing, and the entire machine is automated and under PLC control. The machine is extremely easy to use and straightforward to operate. An automatic air gap adjustment unit and an automatic water temperature control device were added to the high-speed Extrusion Film Non Woven Laminating Machine.

Auto Nonwoven Fabric Laminating Machine with Glue Machine for Film Laminating Coating Cheap Price Flute Laminating Machine Paper

Energy economy, rapid output, and high precision are definitely necessary qualities for a successful nonwoven lamination machine. The dedicated quality and tension controls, two essential components when it comes to the lamination of delicate material to assure the excellent quality of the finished product, are what really set the best machine apart. It's also crucial to keep in mind that the nonwoven lamination machine is a component of a bigger system that also includes machines used for other purposes, and that it must cooperate with these other machines to make sure that the entire system's operation, from start to finish, runs smoothly.

Hygienic Non-Woven Gown Fabric Coating Lamination Making Machine

Over the past few decades, the usage of nonwoven laminates has expanded to a variety of industries, including agricultural, clothes (interlinings, fillers, etc.), home, transportation, and the environment. The following industries employ nonwoven laminates the most out of all the ones that they have, despite there being many more.

High Speed Thermal Film Laminating Machine Automatic Laminated Machine for Protective Clothing with Glue Machine

This laminating machine features two sets of heating systems, and the user can choose between using one set or both sets to save money and energy. It uses a high-temperature mesh belt with an automatic correction function to press the compound into the first layer of the composite coating, which comes out tidy, smooth, with no deviations, etc. strengthening the adhesive fastness, enhancing the drying effect, and making the laminated product soft and washable.